Core Concepts

Core Concepts

Connect with the present and shape the future.Adhere to the principle of putting customer interests first and create higher value for customers.

Enterprise Values

Enterprise Values

Committed to improving and improving the quality of human life.Create higher value for customers

Business Objectives

Business Objectives

Vitalize the industry of the Chinese nation and create a first-class international enterprise.We have built up a reputable company brand throughout the world by years of experience in plastic industry.

Enterprise Spirit

Enterprise Spirit

Pioneering,practical and innovative,scientific management and excellence.We are constantly striving in technological development and product quality control.

Business Policy

Business Policy

Take quality as life,science and technology as leading role and customer satisfaction as tenet.Adhere to the principle of putting the interests of customers first.

-

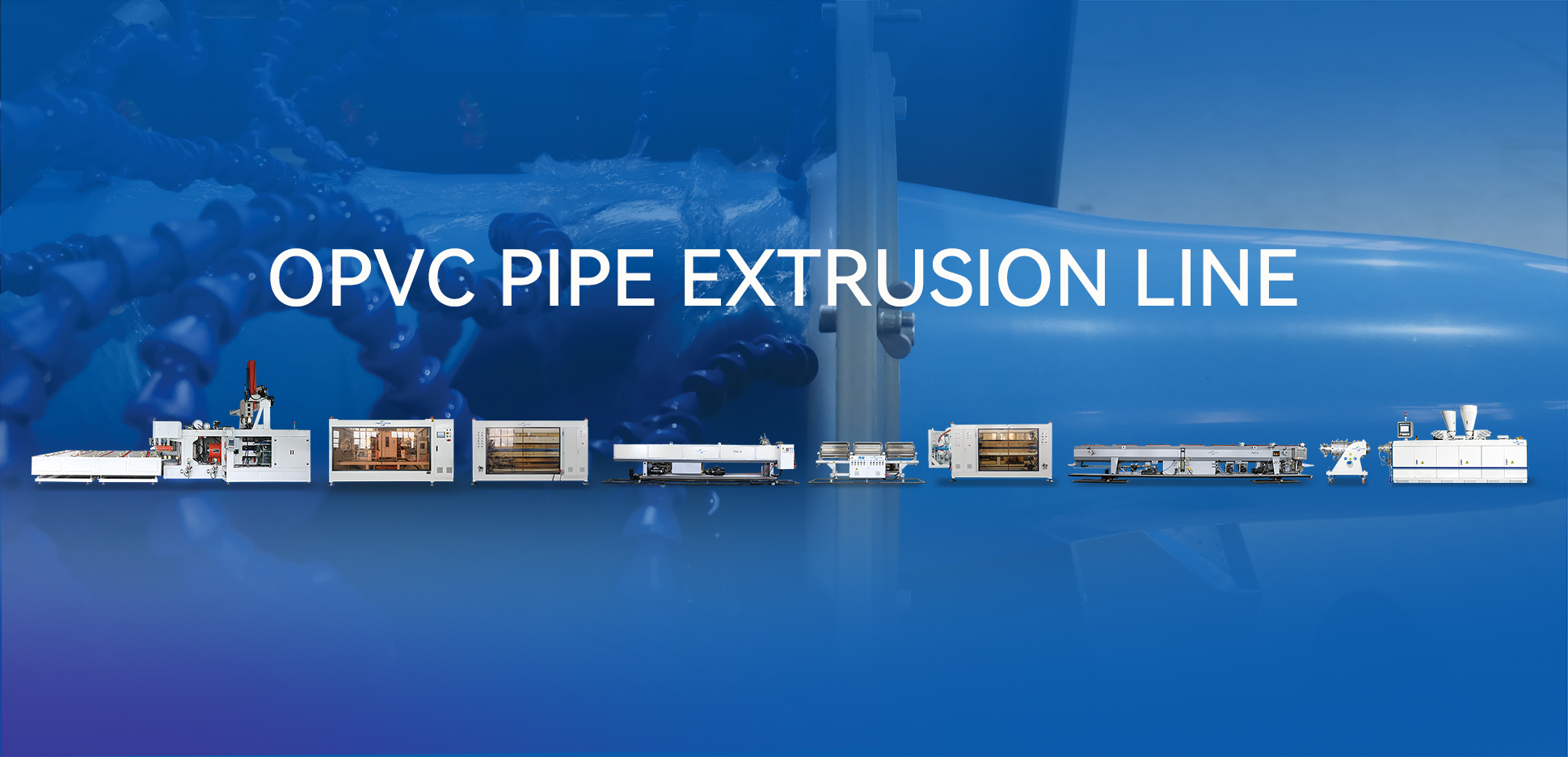

OPVC Pipe Extrusion Machine

The OPVC pipe production line utilizes biaxial stretching technology to produce pipes with superior low-temperature resistance, high toughness, and 15-20% material savings versus conventional methods. Its high-efficiency extrusion system increases output by 25% while ensuring consistent quality. The precision-controlled process guarantees uniform wall thickness and optimal molecular orientation. Ideal for demanding applications, the line delivers high-performance pipes with reduced production time and resource consumption.

View more

-

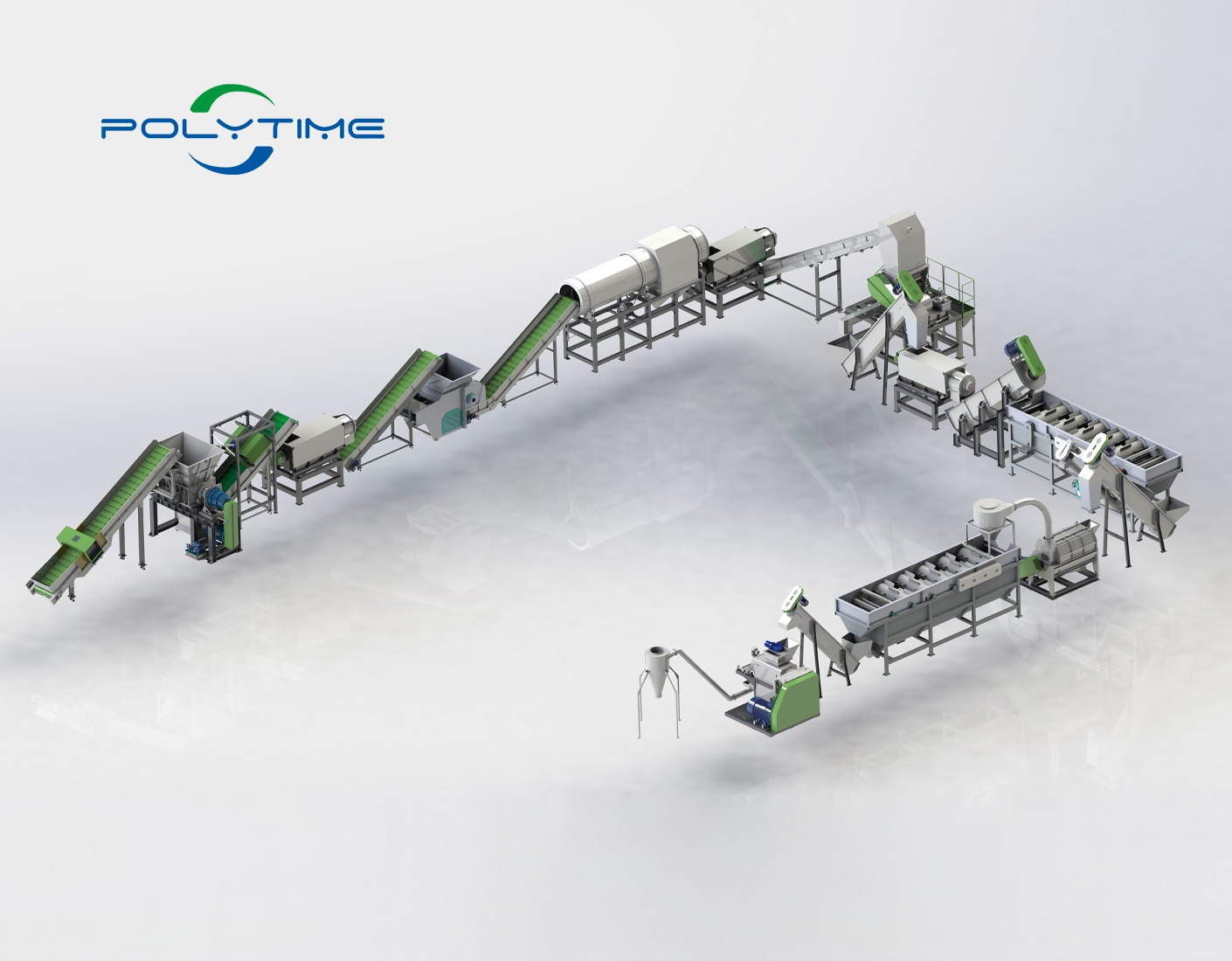

Plastic Recycling Machine

This comprehensive plastic recycling production line is engineered for maximum efficiency in processing post-consumer and industrial plastic waste. The fully integrated system seamlessly combines automated sorting, pre-washing, friction washing, float-sink separation, advanced grinding, hot washing, dewatering, and extrusion pelletizing. It is designed to handle challenging materials like PET, HDPE, and PP, transforming contaminated bales into high-purity, consistent-quality recycled pellets. This robust line emphasizes energy recovery, water conservation, and minimal environmental impact, providing manufacturers with a sustainable raw material to support a true circular economy.

View more

-

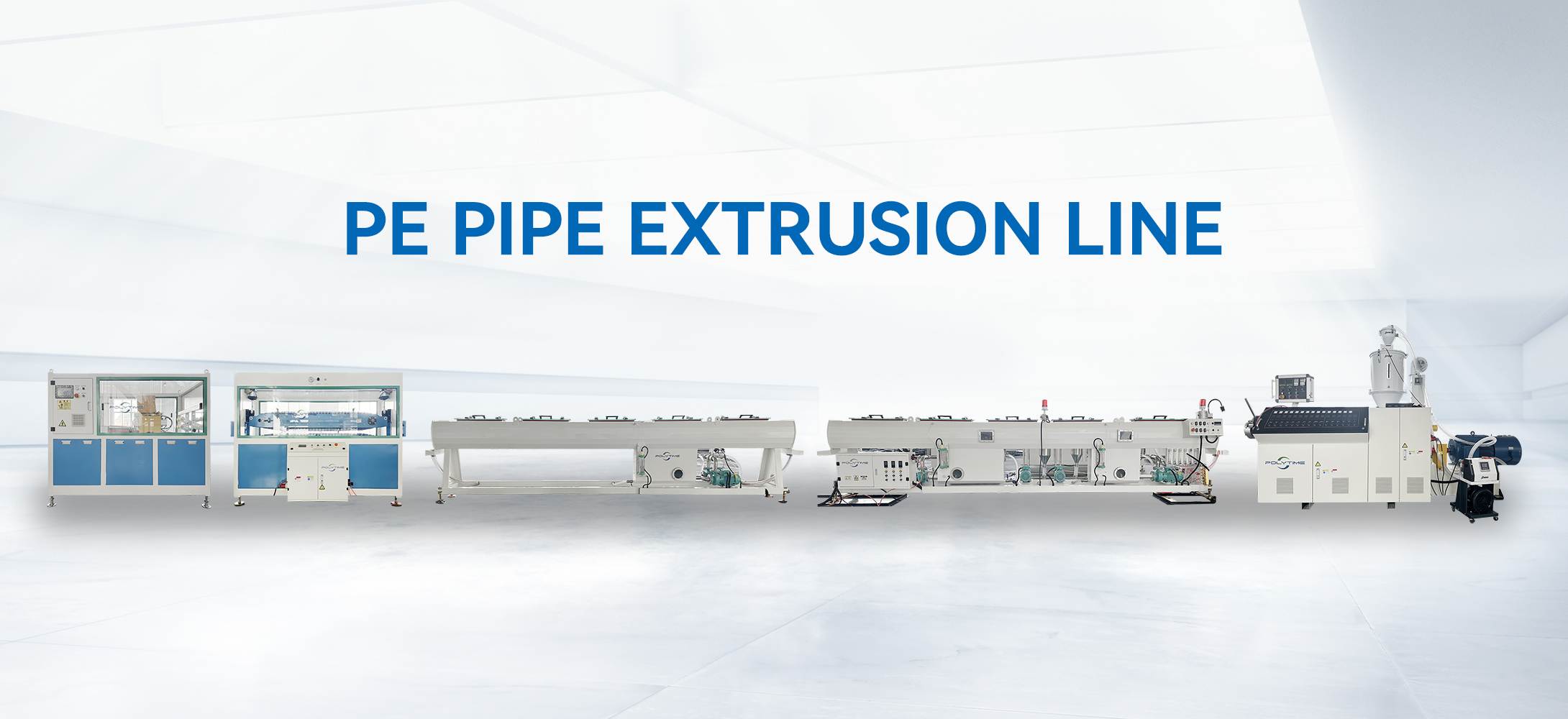

HDPE Pipe Extrusion Machine

Our specialized HDPE pipe manufacturing system delivers high-quality piping solutions with robust extrusion for superior material processing. The line features precise wall thickness control, efficient cooling channels, and automated cutting for consistent production. With advanced fusion technology for perfect joints and energy-saving operation, it produces durable, pressure-resistant pipes ideal for municipal water supply, gas distribution, and industrial applications. The system offers reliable performance with user-friendly controls and low maintenance requirements.

View more

-

Automatic Compounding System

Our advanced compounding system ensures precise material blending with high uniformity for optimal pipe quality. Featuring automatic weighing and dosing for accurate formulations (±0.5%), the line includes high-speed hot/cold mixing with temperature control (±2°C). The modular design allows flexible recipe changes, while dust-proof feeding maintains clean operation. Energy-efficient motors and smart control systems reduce power consumption by 15-20%, delivering consistent output for PVC, HDPE, and specialty compounds.

View more