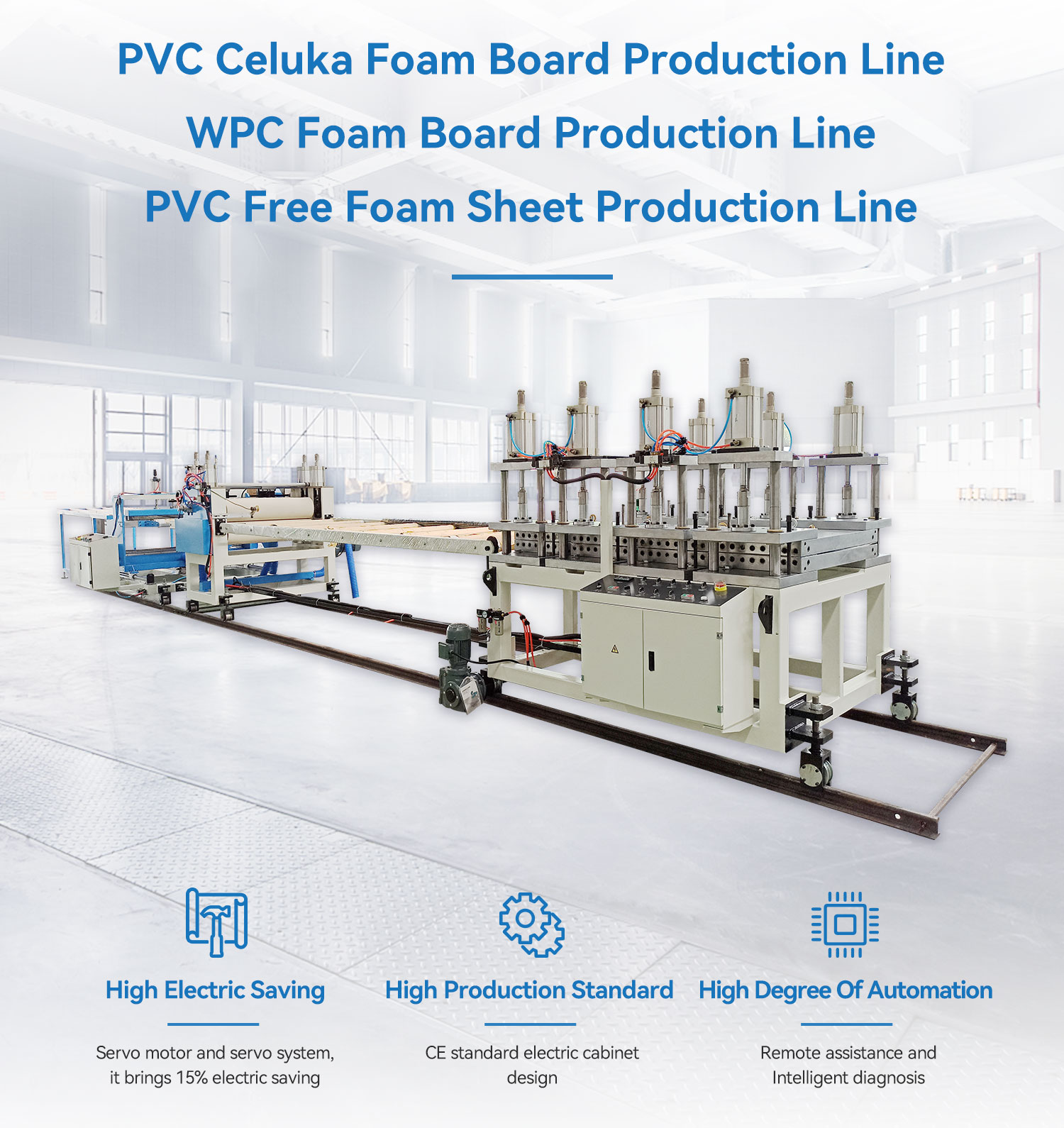

Plastic Board Extrusion Machine

Inquire

- Main Features -

Conical Twin-screw Extruder

Energy

Servo system 15%

Far infrared Heating system

Pre-heating

High Automation

Intelligent control

Remote monitoring

Formula Memory System

Mould

Mould Material

Alloy steel with flow channel chrome plate treatment

Mould Specification

Made with importing technology, chrome plate and bright polish treatment inside. Adjustable screw bolts are available on mould lip for thickness adjustment, 3/1 width adjustable ,with stainless steel heating sticks.

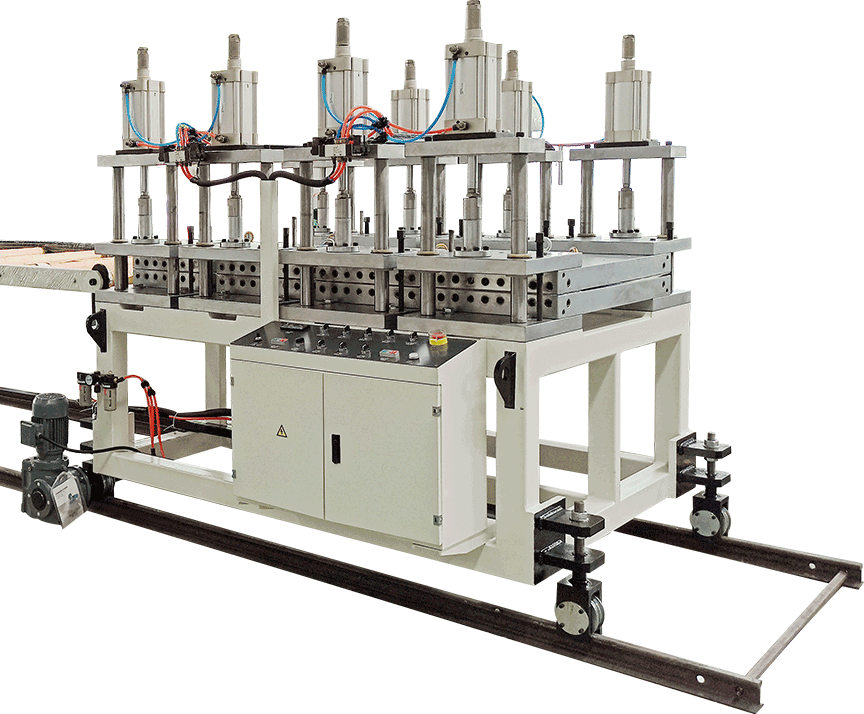

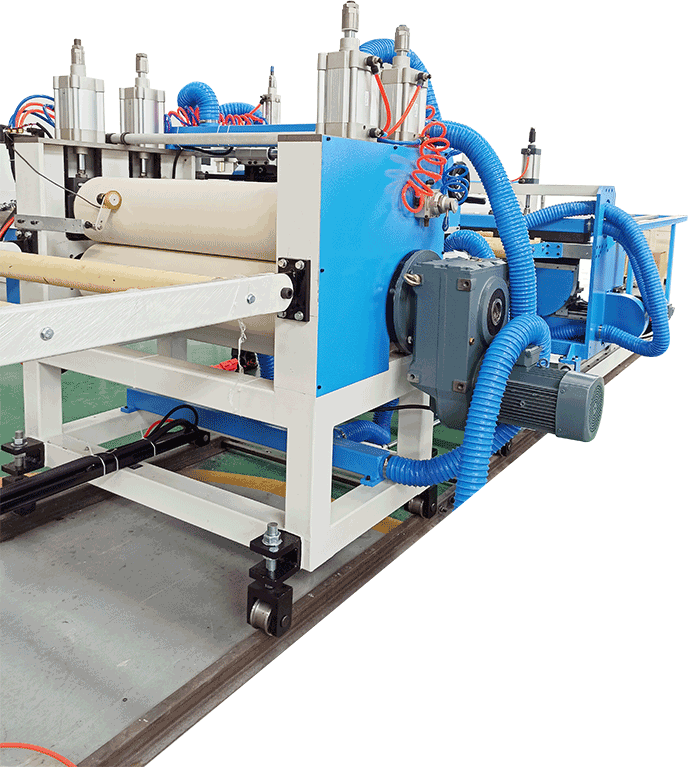

Calibration Table

Safety Performance

The frame is welded by section steel.

Simplicity

The cooling water enters and exits centrally through the collection pipe Adopt quick plug connector, transparent hose for water supply, easy to replace

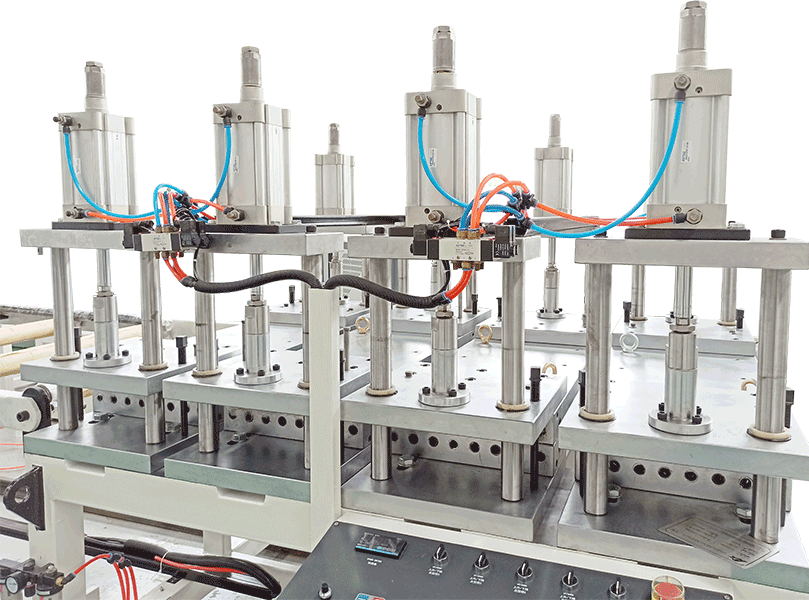

Calibration Mould

Easy Operation

The calibration mould adopts modular design and cylinder lifting, easy to replace and maintenance.

Detail Design

There is a nylon spacer between the side plate and the guide column, which makes the lifting smoother.

Holding Frame

Customization

The length of the bracket can be customized to meet different production needs.

Aesthetics

The roller is made of aluminum alloy, with high reliability and high surface finish.

Convenience

The overall structure is simple, the transportation and installation are convenient

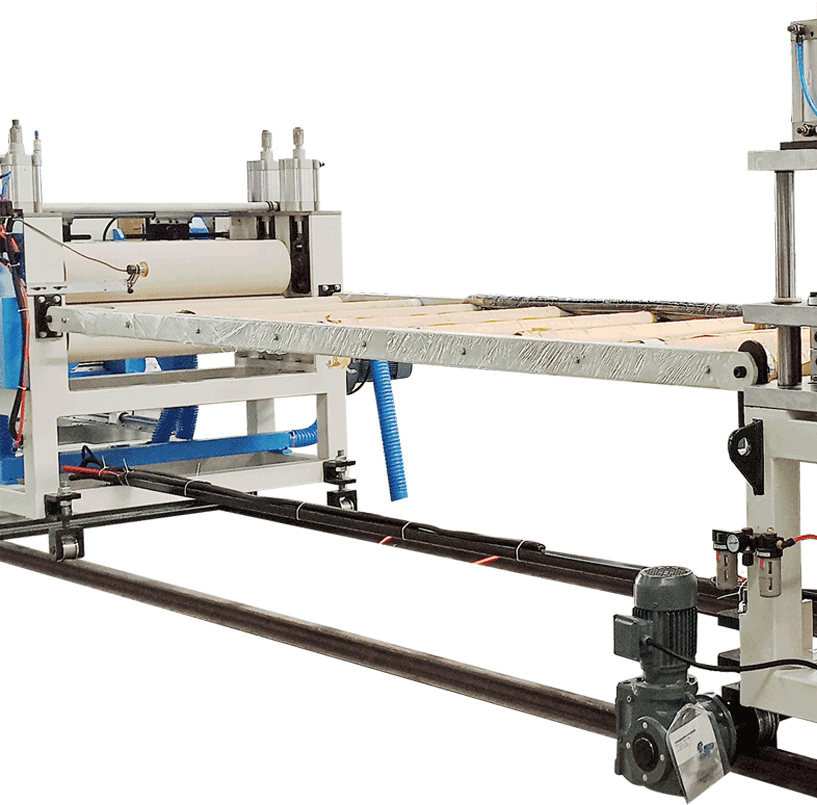

Haul Off

Customization

Configure the number of rollers according to the needs of use

Stability

The traction adopts gear synchronization and compression adopts pneumatic way

Equipped with encoder, the control is more precise

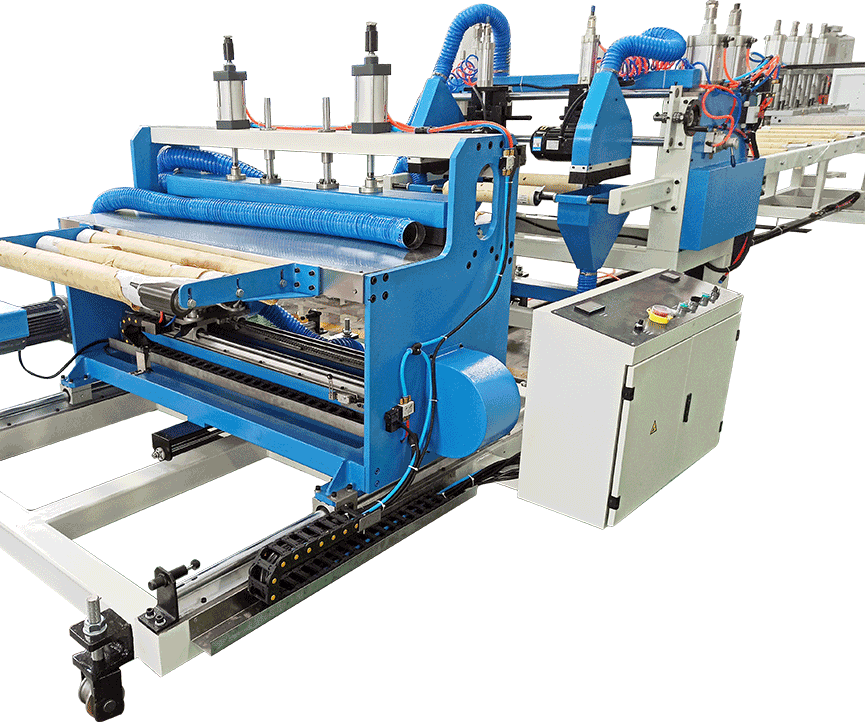

Tracking Cutter

Small Footprint

Using lifting knife, the width of the equipment is smaller

The cutting mechanism is under the table top, the height of the equipment is lowered

Convenience

The left, right, front and back movement of the cutting table are equipped with travel switches for easy control

The cutting length of the sheet is automatic controlled by a meter counter

Stability

We adopt special cutter

The cutting board is driven by a mechanical drive chain, the saw blade is a serrated blade, which is convenient for cutting without burrs

The left and right moving motor is variable frequency motor

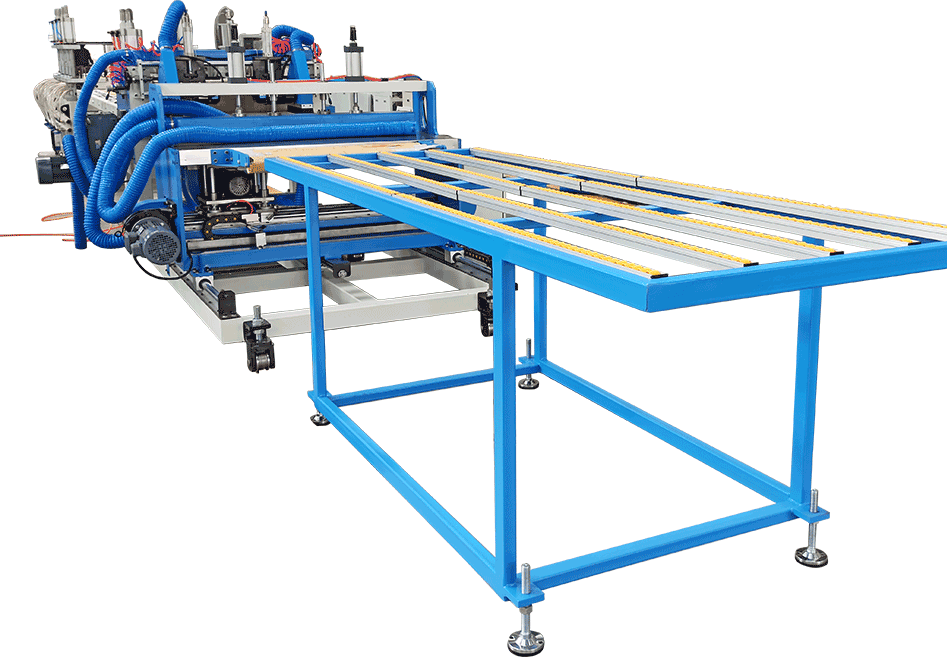

Stacker

The frame is welded by section steel, which is firm and reliable;

The height of the feet can be adjusted, and the versatility is high;

There is a fluent strip on the top, and the plate can slide back and forth;

- Application of the final product -

Transport industry: ship, plane, bus, train, floor covering, core layer, indoors decoration

plate.

Architecture decoration industry: outdoors plate, indoors decoration plate, residential house, office, separation of public building, etc.

Advertisement industry: screen printing, computer engraving, ad. board, exhibition plate, logo plate.

Industrial application: rot proof project in chemical industry, thermal shaped part, plate for refrigeration warehouse, etc.

Other applications: construction mold plate, sports apparatus, aquaculture material, seashore wet- proof facilit, etc.